Our process

From idea to commissioning

Optimal production of power

Quality assured process

Regardless of whether the assignment applies manufacturing or refurbishment, we always perform the same quality assured process, followed by accurate documentation. The outcome is optimised electricity production – now and for the future.

We offer our customers the ability to, in an optimal way, generate and sell electrical power as well as net supporting services.

TURAB offer great knowledge about existing machinery and can, in an efficient way, combine historical and new technology.

1

Technical analysis and refurbishment

Our technicians investigate existing or intended facility on site. Based on the facility`s status and your requirements, we make a proposal.

2

Dimensioning

Our engineers and designers dimension the turbine in accordance with the facility`s and the water body`s conditions. We also create technical basis for a new generator and electrical control equipment.

3

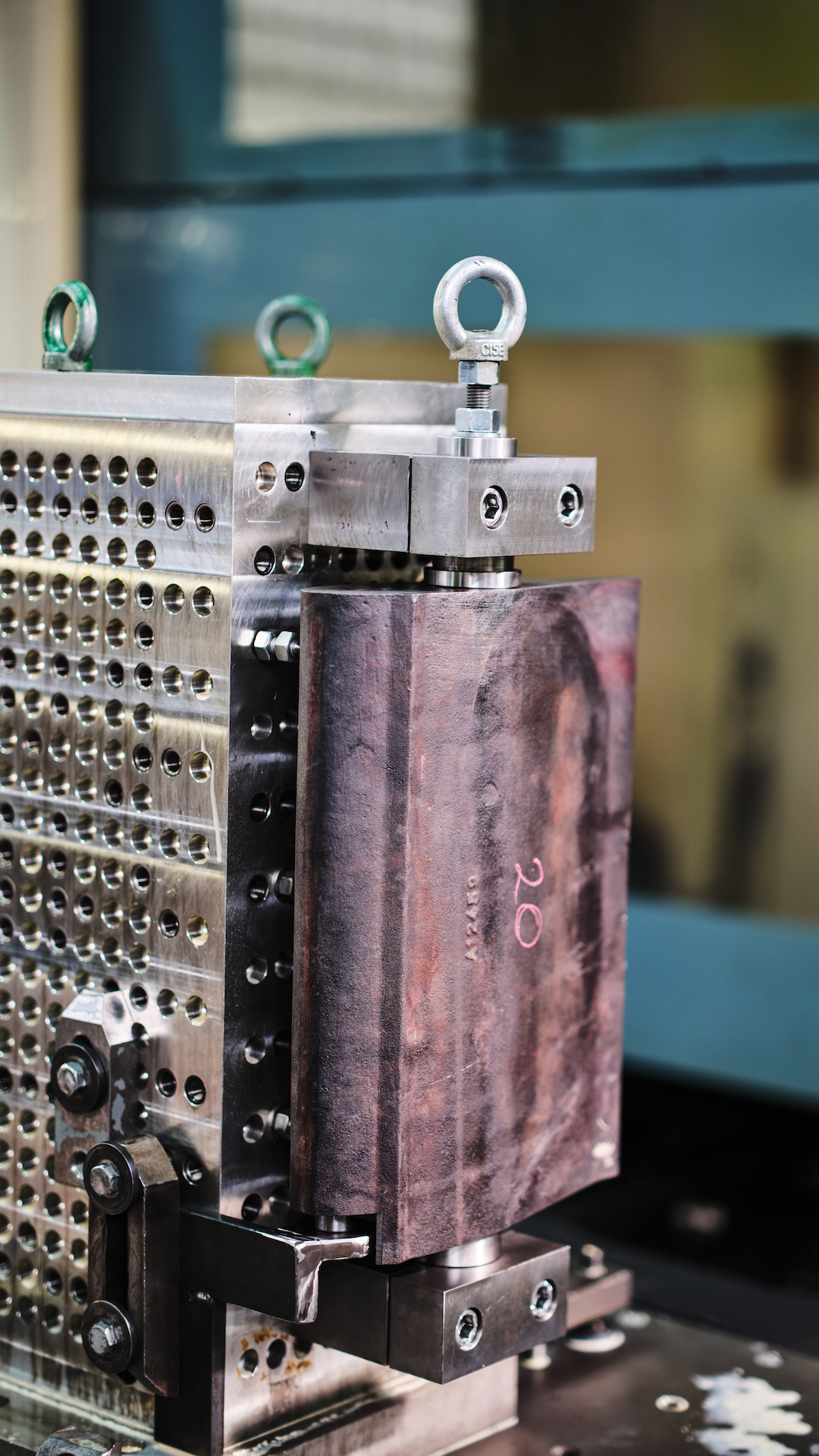

Manufacturing

Manufacturing, refurbishment and modernisation are done in our own, well equipped workshop in Nässjö. Our works has a complete and advanced machinery for welding to machining. Before delivery, the turbine is carefully documented.

4

Disassembly and reassembly

We undertake disassembly and transportation to our workshop. When our work is done, we deliver and do the reassembly, commissioning and follow-up activities.

5

Maintenance and spares

Regular turbine maintenance is crucial for your power plant´s optimal function. We offer service agreements, annual check and follow-up. We carry out analysis as preparation before transfer of ownership or expansion as well as status checks.